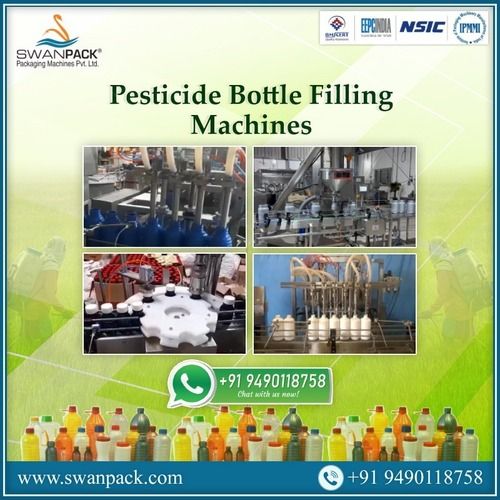

Pesticide Agrochemical Bottle Filling Machine

उत्पाद विवरण:

मूल्य और मात्रा

- 1

उत्पाद वर्णन

Diving nozzle with adjustable depth for different containers to avoid spillage and foaming of the product during filling.

ïFilling accuracy: (+/-) 0.5% of volume.

- Easily adjustable speed of filling according to the product characteristics.

- High grade Teflon seals tightening without opening the product cylinder assembly.

- Single Knob Volume adjustment for all the Nozzles with Horizontal shaft Position Indicator for accurate dose adjustment.

- Long life Pneumatic cylinders which are self lubricating and are maintenance free.

- Imported Gearbox lubrication free and maintenance free.

- Imported Slat chain for conveyor for smooth travelling of the bottles.

- Imported Filter, regulator and lubricator incorporated in the line for pneumatics.

- All electricals are incorporated in SS cabinet.

- PLC from reputed international manufacturer.

- Compressed Air Required: 6 Kg/sq.cm.

- Emergency stop button provided

Makes of Components:

Slat chain from Rexnord, USA. Motor Gearbox assembly from Transtech.

Schneider-Germany Electrical Components and Switches.

PLC of Delta/Innovance/Moons, Sensors from Omron/Sensors.,

Pneumatics from SMC/Janatics or equivalent.

Price: Â

- 50

- 100

- 200

- 250

- 500

- 1000+